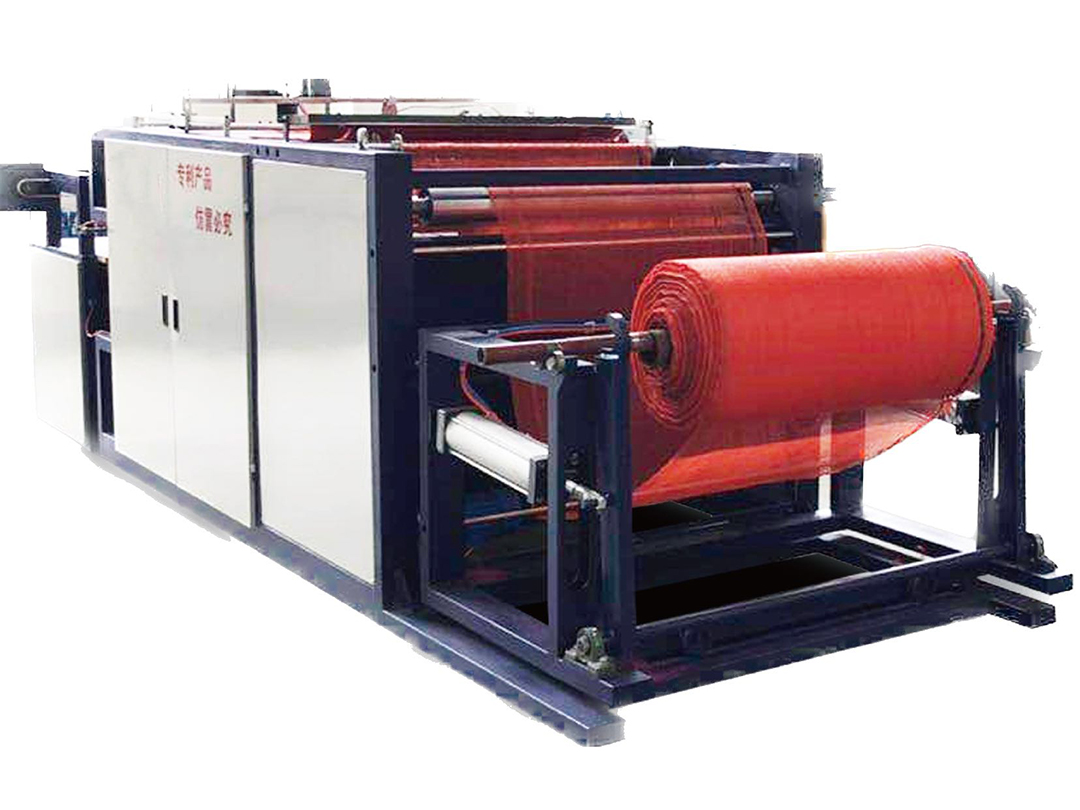

Leno bag Auto cutting and L Sewing machine

Introduction

It is suitable for PP and PE leno bag flat fabric in roll, automatic cutting off, folding and sewing, bottom sewing.

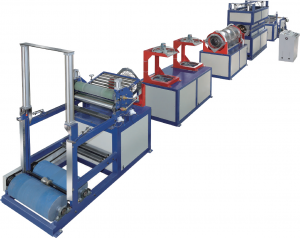

From fabric uncoiler—auto color mark tracking—thermo cutting---sidewise folding---conveying by mechanical arm----belt conveying---sewing (single or double folding optional)—another side conveying---bag bottom sewing (single or double folding optional)---finished bag automatic counting and stacking.

The woven cloth will be automatically thermally cut off in a fixed length and sewed, and laborsaving can be realized. Driven by servo motor, the length of bag can be precisely controlled. Sticking is avoided after the bag being thermally cut off. The machine will stop automatically when the cloth is over. Pneumatically driving is adopted in cloth releasing and can be easily operated.

Characteristics:

PLC control, touch screen operation.

Servo motor bag feeding, high cut to length accuracy

System alarm, electric problem, working condition will show on touch screen.

Special thermo cutting blade

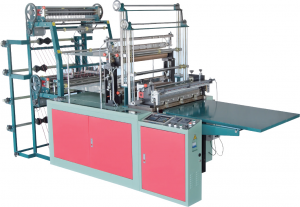

Equip with mesh bag width wise folding device

Main electric parts using Taiwan brands, more reliable

China first invention: down press mechanical arm, to make sure bag piece delivery stable and rapidly.

Bag bottom can be single or double fold and sew.

Specification

| Max. dia. of unwinding cloth | 1200mm |

| Bag width range | 400-650mm |

| Bag Length range | 450-1000mm |

| Length accuracy | ±2mm |

| Bottom folding width | 20-30mm |

| Production capacity | 15-21pcs/min |

| Stitching range | 7-12mm |

| compressed air supply | 0.6 m3/min |

| Total motor | 6.1 kw |

| Heating power | 2kw |

| Weight (About) | 1800kg |

| Overall dimensions (L×W×H) | 7000×4010×1500mm |