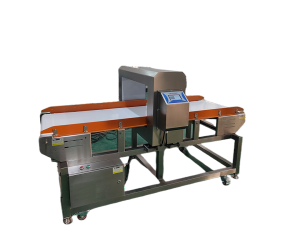

Metal Detection Machine for Jumbo Bag

Features

1、The latest generation of digital signal processing (DSP) technology and intelligent algorithm are adopted to improve the detection accuracy and stability; It is also the only metal detection machine using DSP technology in China.

2、German automatic filtering technology can effectively suppress the product effect;

It can detect products with relatively high efficiency, such as frozen food, meat, rice, pickled products, fish paste, etc;

3、With intelligent setting, the equipment can automatically set the best sensitivity suitable for the tested product, and the operation is simple and convenient.

4、Memory function: save the best sensitivity, which can be directly detected in the next test, and can store the detection parameters of 12 products;

5、 LCD screen display, Chinese and English menu screen, easy to achieve man-machine dialogue operation;

6、It can detect iron, stainless steel, copper, aluminum, lead and other metal materials

7、 Flexible digital sensitivity control mode and various advanced manual setting functions; Various specifications can be selected to adapt to different material detection sensitivity requirements;

8、 Made of all stainless steel SUS304, high grade protection motor is optional; The highest IP69 protection grade is suitable for particularly harsh working environment;

9、Simple detachable rack, convenient for users to clean; The special design of the conveyor belt prevents the conveyor belt from deviating.

10、Multiple elimination methods are available; Precise removal control ensures reliable removal of foreign matters with minimum material waste.

Specification

|

Applicable Test Products |

Jumbo 25KG |

|

Detection Channel Size |

700mm(W)*400mm(H) |

|

Machine Length |

1600mm |

|

Height of conveyor belt to the ground |

750mm+50 |

|

Alarm Mode |

Audible and visual alarm |

|

Conveying Channel Quality |

Food Grade |

|

Weight |

Within 200KG |

|

Voltage |

Single Phase AC 220V 50/60Hz |

|

Temperature |

0℃-40℃ |

|

Sensitivity |

Without Running Φ Iron:1.5 Non-Iron 2.0 stainless steel2.5mm |

|

Size after packing |

1600*1200*1200mm(Estimate) |

|

Remark:The sensitivity will change due to the influence of environment, product effect and other factors, subject to the actual on-site product test |

|

Product Inspection

(1) Pre-packaging detection: This reduces the packaging costs and avoids the impact of packaging materials on metal detectors (such as aluminum platinum packaging). Pre-packaging detection can be used, which is the most effective and the best detection method

(2) Post-packaging inspection: The rise of labor costs has promoted the continuous improvement of production automation in many enterprises. Metal detectors can be connected to the automatic packaging system to fully improve the production efficiency and detection efficiency of customers. Post-packaging inspection is the last step of the product production process and the safest detection method

(3) Linkage function: metal detector reserves 24V pulse signal, which can be linked with customer equipment and assembly line;

(4) Rejection Device: the metal detector can customize the appropriate removal device according to the customer's detection products.