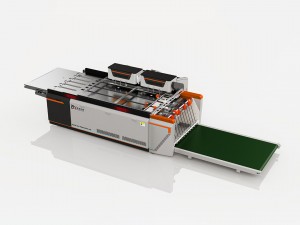

BX-PPT1300 Paper-plastic Tubing&Cutting machine

Introduction

BX-1300B paper and plastic cylinder molding middle seam bonding pouch machine, this item adopt to the most advanced structure and craft to satisfy many kinds of printing. It adopt the technology of coating composition with PP or PE material to laminate plastic film on double surface of PP and PE woven sack.It can produce the seam folding bag , non folding bags, flat bags and other different types of packing bags. From substrate-printing-cylinder molding-cutting- folding bag. The whole process is set with advanced electrical systems and mechanical devices. It is widely used in making sacks for foodstuff, chemical, cement, feed and other industries.

Specification

| Type of bag | Folding bag, non folding bags, flat bags, sewing bags of color film |

| Width of bag | 350-610mm (adjustable) |

| Length of bag | 410-1200mm (flat) |

| Folding width | 50-200 ( adjustable) |

| Maximum roll diameter of fabric | ≤Φ1300mm |

| Maximum width of fabric | 1300mm |

| Output: | 20-150 bags/min.(bag length 800mm) |

| Overall dimension | 14.5m*4.58m*2.5m |

| Power supply | Three-phase 38V/220V 50H |

| Weigh | About 15T |

Feature

1. Main control system adopts PLC and touch screen HMI from Germany Siemens with programmable ratio interlinked speed regulation, trouble interlock.

2. Emergency stop buttons are placed on all operation position to ensure safety.

3. Temperature control system adopts Digital Temperature Controller from Japan RKC and USA CRYDOM solid state relay with self-adapted effect quick to rectify process temperature and improve temperature control accuracy.

4. Driving system is equipped with an inverter from Japan YASKAWA.

5. Tension system adopts tension controller from China consisted of tension transducer, tension controller and magnetic powder brake (Taiwan), hi-reliability and hi-automation.

6. Machine operation by console and panel on site.

7. Protection grade for cabinet IP21.

Our Advantages

1. We has two factories of 10000 square meters and totally 100 employees to promise the Honed Tubes In Stock best quality control;

2. According to the cylinder pressure and inside diameter size ,different hydraulic cylinder honed tube Would be choosed ;

3. Our motivation is --- customers’ satisfaction smile;

4. Our believing is --- pay attention to every detail;

5. Our wish is ----perfect co-operation

FAQ

You can contact any of our sales person for an order. Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For designing or further discussion, it is better to contact us with Skype, or QQ or WhatsApp or other instant ways, in case of any delays.

Usually we quote within 24 hours after we get your inquiry.

Yes. We have a professional team having rich experience in design and manufacturing.

Just tell us your ideas and we will help to carry out your ideas.

Honestly, it depends on the order quantity and the season you place the order.

Alway 60-90days based on general order .

We accept EXW, FOB, CFR, CIF, etc. You can choose the one which is the most convenient or cost effective for you.