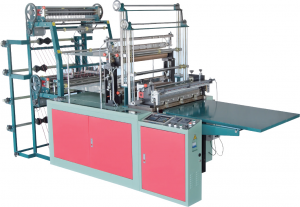

BX-TG650 Twist & Gusset Machine for Woven Bag

Specifications

|

Item |

Parameter |

Remarks |

|

Fabric width |

350-650mm |

|

|

Fabric Diameter |

Φ500-1500mm |

|

|

Gusset speed |

Max 150m/min |

|

|

Gusset depth |

Max 100mm |

As client’s request |

|

Total power |

13kw |

|

|

Air Consumption |

0.2M3/min |

|

|

Machine weight |

About 2.5T |

|

|

Dimension (lay-out) |

7500x1300x1600mm |

Each machine consists of

| S/N | Description | Main Part | Model | Quant. | Manufact. | Remarks |

| 1 | Unwinder | Unwinding Unit | 800 | 1set | Pea Shinn | The Unwinder is equipped with Auto Elevator to load fabric automatically, easy operation. EPC equipped, auto Tension control |

| Pneumatic Brake | 1set | Taiwan | ||||

| Air Shaft | 2pcs | Chinese | ||||

| Hydraulic Cylinder for Fabric Loading | 1set | Chinese | ||||

| EPC | 1set | Chinese | ||||

| Auto Tension Controller | 1set | Pea Shinn | ||||

| 2 | Twist & Gusset Unit | Twist Unit | 800 | 1set | Pea Shinn | Manual & adjustable twisting device, easy operation. Step by step gusseting device, |

| Gusset Unit | 800 | 1set | Pea Shinn | |||

| Gusset Wheel | 1set | Pea Shinn | ||||

| Nip Unit | 800 | 1set | Pea Shinn | |||

| Nip Motor | 5.5kw | 1set | Siemens | |||

| Inverter | 5.5kw | 1set | Yaskawa | |||

| 3 | Rewinder | Central Rewinding Unit | 800 | 1set | Pea Shinn | Central winding type, keep winding even and tight. auto tension control with inverter control speed |

| Air Shaft | 800 | 1set | Chinese | |||

| Press Roller | 800 | 1set | Pea Shinn | |||

| Winding Air Shaft | 2pcs | Chinese | ||||

| Rewinding Motor | 5.5kw | 1set | Siemens | |||

| Inverter | 5.5kw | 1set | Yaskawa | |||

| Auto Tension Control | 1set | Pea Shinn | ||||

| Air Cylinder for Fabric Unloading Device | 1set | Pea Shinn |

Feature

1. Twist & Gusset online, accurate twisting & Gusseting position

2. The Unit could be used for Twist & Rewinding, or Gusset & Rewinding, or Twist & Gusset & Rewinding separately.

3. Fully auto tension control

4. EPC equipped for unwinding

Our Advantages

1. We has two factories of 10000 square meters and totally 100 employees to promise the Honed Tubes In Stock best quality control;

2. According to the cylinder pressure and inside diameter size ,different hydraulic cylinder honed tube Would be choosed ;

3. Our motivation is --- customers’ satisfaction smile;

4. Our believing is --- pay attention to every detail;

5. Our wish is ----perfect co-operation

FAQ

You can contact any of our sales person for an order. Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For designing or further discussion, it is better to contact us with Skype, or QQ or WhatsApp or other instant ways, in case of any delays.

Usually we quote within 24 hours after we get your inquiry.

Yes. We have a professional team having rich experience in design and manufacturing.

Just tell us your ideas and we will help to carry out your ideas.

Honestly, it depends on the order quantity and the season you place the order.

Alway 60-90days based on general order .

We accept EXW, FOB, CFR, CIF, etc. You can choose the one which is the most convenient or cost effective for you.