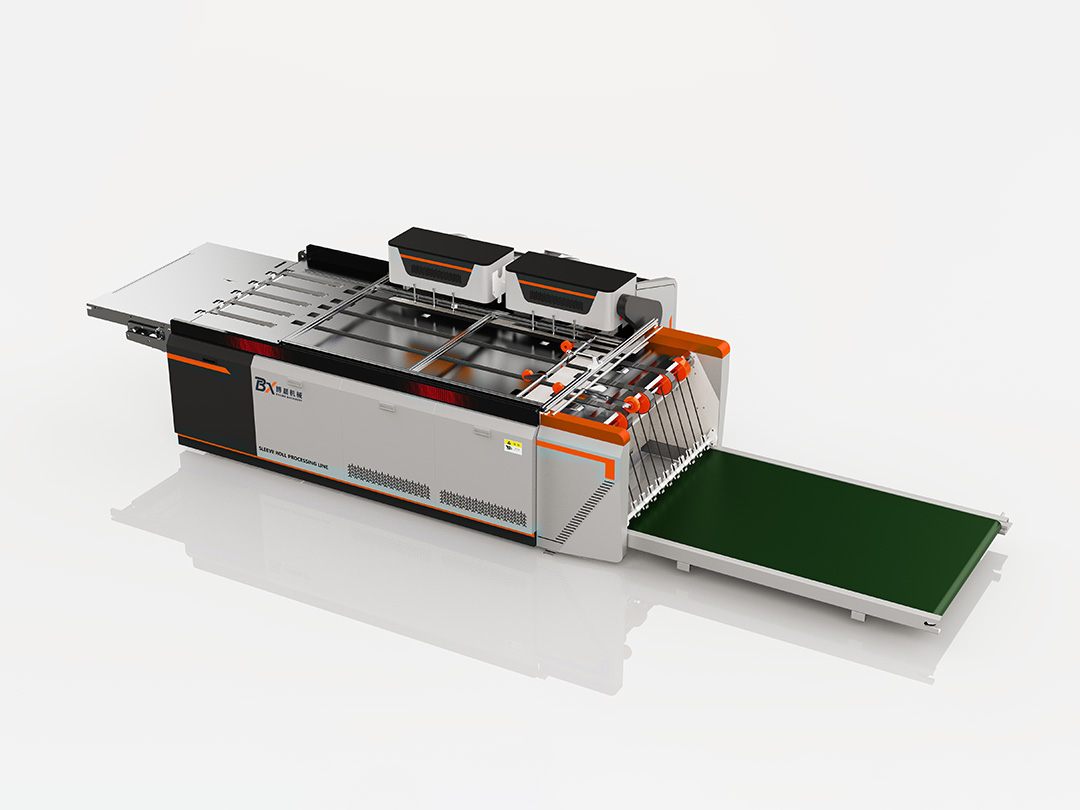

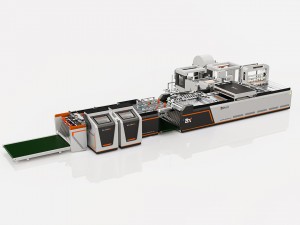

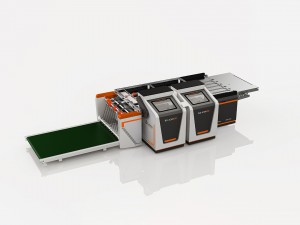

BX-LAH650 Ultrasonic Bag Mouth-Liner Hemming Machine For Woven Bags

Video

Specifications/Technical parameters/Technical Data

|

Item |

Parameter |

|

Fabric Width |

380-450mm |

|

Fabric Length |

500-1200mm |

|

Liner longer than Outer Bag |

3cm-10cm |

|

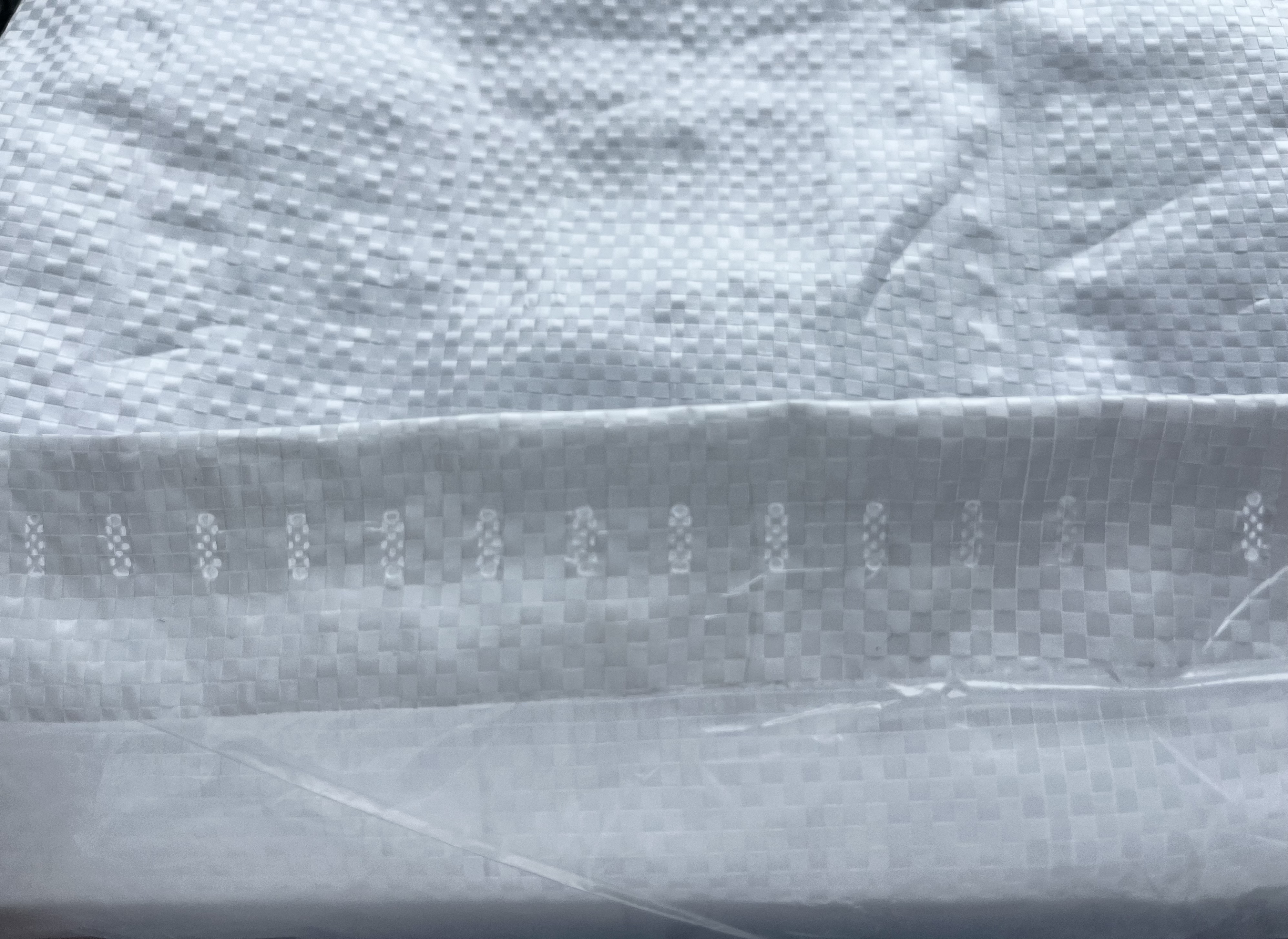

PE Film Thickness |

≥0.015-0.05mm |

|

Machinesion Speed |

15-18pcs/min |

|

Power connection |

15KW |

|

Voltage |

Customer specified |

|

Air Supply |

≥0.3m³/min |

|

Machine weight |

About 2.1T |

The different between Ultrasonic and Heat Hemming

1. The Next Section adopts ultrasonic hemming method, which has no residual heat residue and will not scab or fall off over time, meeting the requirements of food grade packaging bags;

2. Low production temperature will not cause environmental pollution (temperature and smoke) in production;

3. The maintenance cycle of Ultrasonic is short, and there is no need to clean the plastic thermal adhesive on the cutting kinfe

4. Ultrasonic is more energy-efficient than Heat Hemming.

Product Details

Application: 1.With Liner Inserted Bag / And Also Normal Bags Without Liner Insertion.

2.With Laminated Woven Fabric /And Also Non-Laminated Woven Fabric.

Price: Negotiable

Voltage: 380V 50Hz, the voltage can be as local demand

Payment term: TT,L/C

Delivery date: Negotiable

Packing: export standard

Market: Middle East/ Africa/Asia/South America/Europe/North America

Warranty: 1 year

MOQ: 1 set

Features

1. Applicable for laminated or non-laminated bag,with liner or non-liner woven bag.

2. Auto align with PE liner and outer bag

3. Visual interface operation system

4. Full sets of Mitsubishi Electrical system

5. Hemmed or not hemmed are OK.

6.Please ensure the finished bag top can be opened easily,and the hole should be at least 8cm from the bag top.

Applications