Cutting & Valve Making & Sewing Machine for Woven Bags(With twist and gusset function)

Product Video

Introduction

For this machine.The Unwinder is equipped with Auto Elevator to load fabric automatically, easy operation. EPC equipped, dancing Roller control Tension, Inverter control unwinding speed.

Manual & adjustable twisting & Gusset device, easy operation. Step by step gusseting device. Take-up unit controls tension, dancing roller makes gusseting firmly.

Servo Motor controls feeding, Double Cam design for stable running. Mark Sensor to detect printed fabric, Servo control feeding length for non-printing fabric, achieves accurate cutting. Vertical & Heat Cutter with bag mouth open system for normal fabric, cold cutter for Laminated fabric. PLC & Inverter control cutting speed, sync control.

Servo motor transfers woven bag after cutting, achieves precision transferring and stable running, Second Bag Mouth Open to makes sacks open mouth completely, and make Valve easy.

Valve Making by servo control, the size of Valve could be adjusted and the cutting unit to make the Valve Bag match the good sizing and looking.

Two sets of Sewing Heads to sew the bottom and mouth on line. Equipped with single folding device, Inverter control sewing speed, the position of second sewing unit could be adjusted to match different size of sacks. PLC & Inverter for sync control.

Sensor & PLC control, Auto Counting, Stacking & conveyor-belt advancing.

Specification

|

Item |

Parameter |

Remarks |

|

Fabric Width |

370mm-560mm |

with Gusset |

|

Max Diameter of Fabric |

φ1200mm |

|

|

Max. Bag Making Speed |

30-40pcs/min |

Bag within 1000mm |

|

Finished Bag Length |

550-880mm |

After Valve Cutting, Folding & Sewing |

|

Cutting Accuracy |

≤5mm |

|

|

Max Valve Size |

Max 120x240 |

Height x Width |

|

Max. Sewing Speed |

2000rpm |

|

|

Gusset depth |

40-45mm |

As client’s request |

|

Stitch Range |

Max 12mm |

|

|

Folding Width |

Max 20mm |

|

|

Power connection |

19.14kw |

|

|

Machine weight |

About 5T |

|

|

Dimension (lay-out) |

10000x9000x1550mm |

Feature

1. On line cutting & Valve Making & Two sides Sewing, could do Cutting & Sewing as well

2. Servo controlling for cutting accuracy

3. On line Twisting & Gusseting

4. Vertical Heat Cut for Normal Fabric, Cold Cutter for Laminated Fabric

5. Edge Position Control (EPC) for Unwinding

6. Servo Manipulator to transfer the Woven Bag after cutting

7. PLC Control, Digital Display for Operation Monitor and Operation Setting

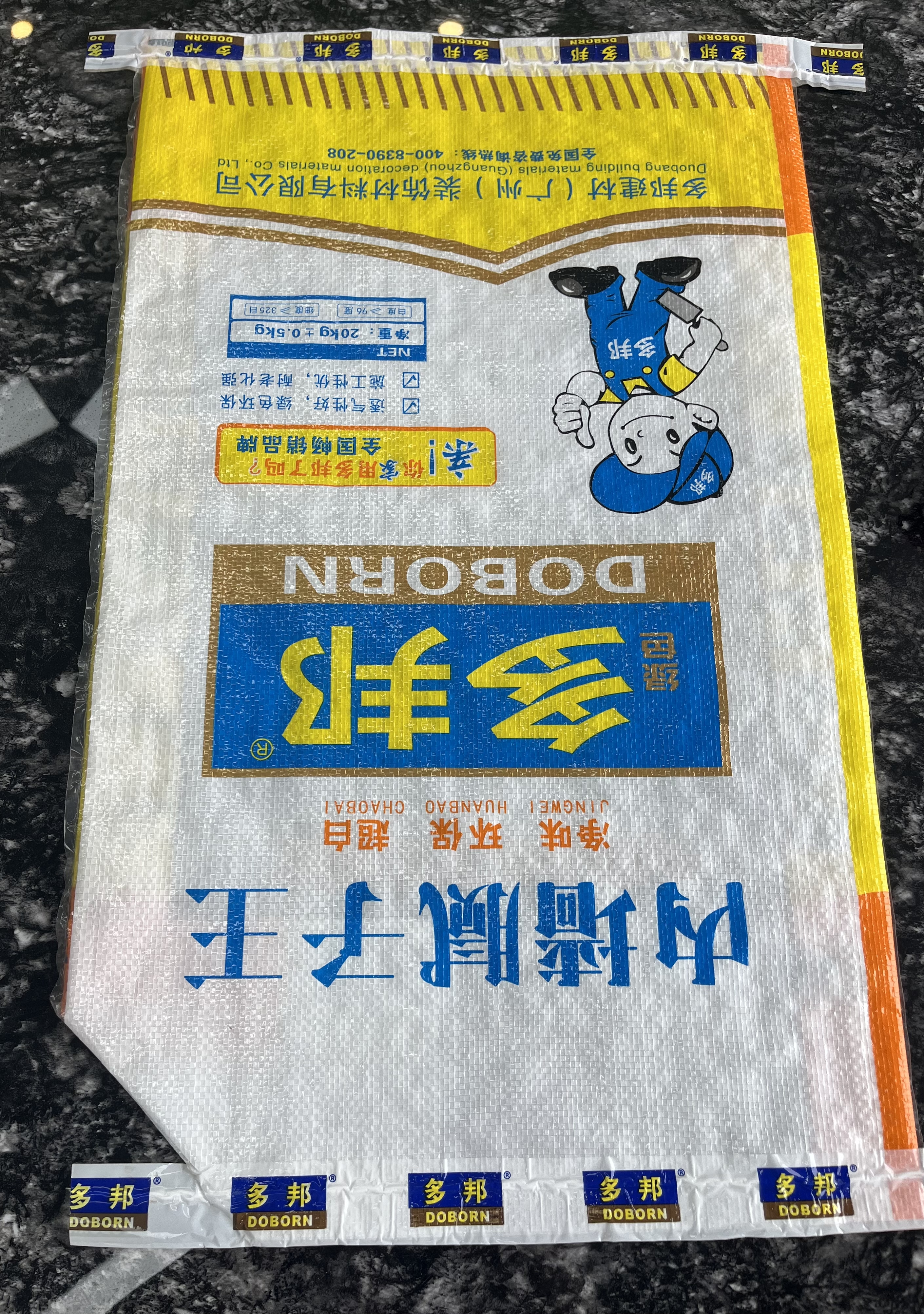

Applications